The built environment has a hot water distribution problem. There historically haven’t been any analytical tools available for hot water distribution systems. Utilities and states couldn’t compare different distribution system approaches and use that analysis to decide what systems to encourage and discourage. California’s Title 24 can’t reward builders for installing advanced, well-designed systems because there aren’t any models they can implement to let builders demonstrate that their systems perform well. Designers and builders can’t perform detailed analysis on their designs to ensure that they’re creating quality systems.

The Solution

At Beyond Efficiency, Inc. we’re developing the solution. We’re currently in the process of developing Python-based simulation models of hot water distribution systems. These tools will provide a cost-efficient means of answering all the industry’s hot water distribution questions.

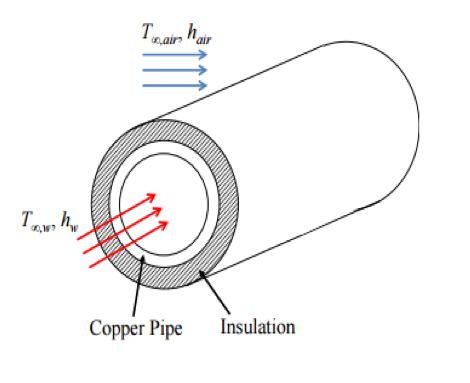

The core of the hot water distribution model is a Python-based, multiple-node simulation model of a single pipe. This pipe can capture the following effects:

- Heat loss to the environment,

- Heat change impacts of water flowing through the pipe,

- Different pipe sizes and materials,

- Different insulation conductivity and thickness

Through these capabilities, you can predict the performance of any pipe they desire. This allows you to cost-efficiently predict the thermal performance and hot water delivery characteristics of any pipe that you desire. The pipe model is also designed to accept the outlet water from one pipe as the inlet water to another, making design and modeling of distribution systems a natural next step.

Figure 1: Schematic Showing Heat Transfer Processes in Pipes (Image Credit: Chegg Study)

Current Status of the Pipe Model

Currently, the pipe model is a thermal analysis tool. It performs energy balance calculations on the water stored in the pipe and tracks the water as it passes through the pipe to the outlet. It reads a user-friendly .csv file to obtain the draw profile. It’s capable of being analyzed repeatedly, with user-specified timesteps, to model the pipe over time. This makes it a useful tool for tasks such as:

- Identifying the availability of hot water in the distribution system after a delay period and determining whether or not it’s hot enough to satisfy the next draw,

- Predicting the hot water delivery performance of different distribution systems based on metrics such as unmet demand, water waste, and time to tap,

- Calculating the energy lost from the distribution system and estimating the impact that has on the building heating and cooling load,

- Comparing the potential performance and energy saving impacts of different distribution system types, insulation levels, and pipe materials.

Long-Term Vision

The distribution system model is currently a thermal model of a single pipe. It has the capabilities needed to create a simulation model of individual pipes. But this is only a starting point.

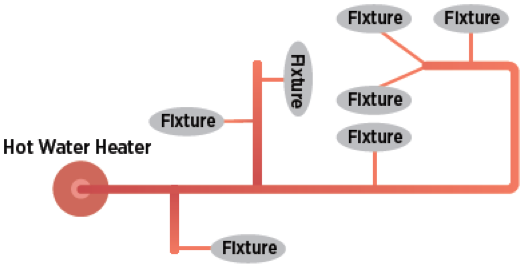

Distribution Systems

The next step in the project is to combine pipes to create models of an entire distribution system. This can already be done by setting the inlet water of one pipe to be the outlet water from a different pipe. While it can be done, currently it’s not user friendly. The next step in this process will be to create additional functions that can combine multiple pipe models into a single distribution system model. In this way you can simulate entire distribution systems with much cleaner, easier to understand code than in the current implementation.

Figure 2: Schematic of a Trunk and Branch Distribution System (Image Credit: Environmental Protection Agency)

Pressure Loss Calculations

The third step in this process will be adding flow calculations. The model currently reads a .csv file specifying the flow rate at each fixture, but we all know this isn’t how distribution systems work. Turning on a shower doesn’t always yield precisely 2.0 gal/min. Real flow rates are based on the mains supply pressure, the outlet ambient pressure, and the pressure drop in the distribution system. Some systems employ pumps, where the flow rate it based on the pump input and the pressure drop in the system. We’ll eventually add pressure calculations to the models so they can predict flow rates as well, making them more useful as design tools.

Wrapping It Up

Beyond Efficiency is currently developing simulation models of hot water pipes and distribution systems. With these models, we will be able to help you answer questions you have around the impacts that distribution systems design has on energy consumption and hot water delivery performance. We’re anticipating supporting states and utilities creating incentive structures, consultant teams updating California’s Title 24, and designers and engineers creating buildings. But we haven’t thought of everything. What applications would you have for these models? What features would you need included for them to be useful? Don’t hesitate to let us know!